| Home |

| What's New |

| Videos |

| Pictures |

| Donations |

| Webcams |

| Sponsors |

| About us |

| Contact |

| Archives |

| How we do it |

| Quick facts |

| Awards |

| Comments |

| Credits |

| FAQs |

| Lost/Found |

2, 4, and 8 Channel Boxes

| Setup Status Power Distribution Computer Control Buffer Boards Channel Boxes Snowball Fight Driveway Arches |

Donation Box Grass Grid Roof Grid LED Mega Tree Trees Leaping Arches |

This page describes how we made the main switching circuits for the 2, 4 and 8 channel boxes. The 2 and 4 channel boxes are utilized under the trees, the roof, and by the driveway for the scrolling lights. The 8 channel boxes are used for the lights on the roof grid.

|

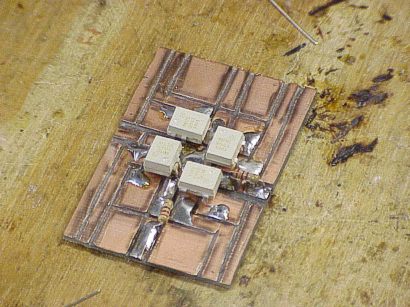

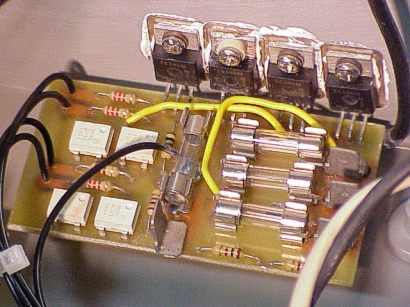

Here, we see all the components attached to the board. The boards' traces are tinned to help increase the ampacity rating. This board is now ready for the next step, which is placing the wires on it. |

|

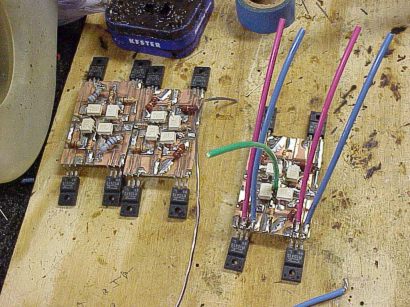

Just another pic of the 4 Channel boards. Here we had 3 sets waiting to have the power leads soldered on. |

|

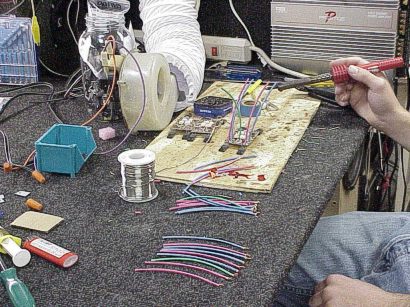

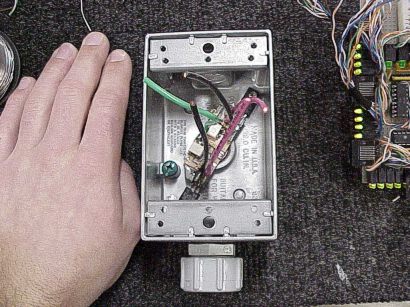

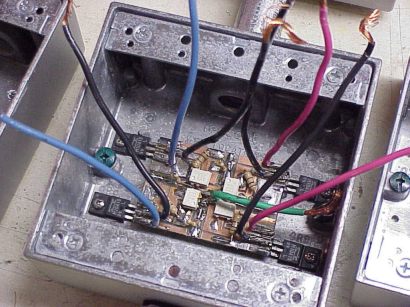

Here's a 4-channel board installed in a 2-gang metal box. The control wires are added in the next picture. |

|

Another layout showing (2) boards installed, and a terminal strip for the control wire connections. |

|

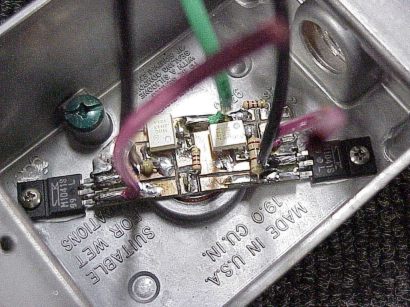

Here, we see all the wires are installed with the spade terminal connections. |

|

Similar to the above picture, this view doesn't have the hand in it, but also shows the low voltage terminal strip. |

|

The 8 channel box is ready to go! (1) 14 awg, 3-conductor SOOW water-resistant wire feeds the box, while multiple 16awg wires exit the box, each acting as an individual channel. |